This post is part of Plyco’s Guide to MDF.

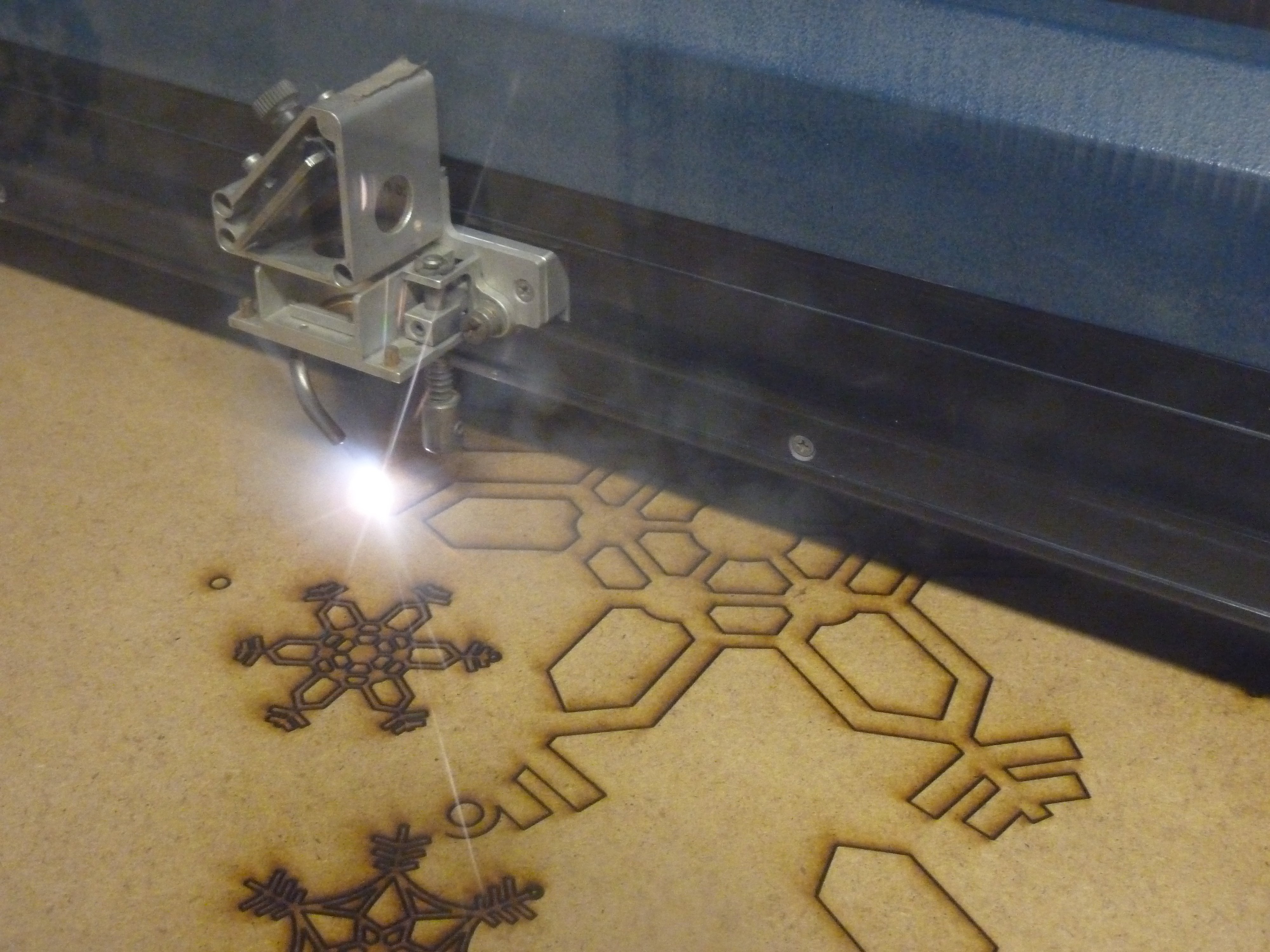

In recent years there has been a serious surge in the popularity of laser cutting. Laser cutters have been becoming more and more affordable, meaning the gateway to this aspect of woodworking has been thrown wide open for anybody from professionals to those who want to make occasional crafts as a hobby. As a result of this increased popularity, there has also been a rapid increase in the need for laser cutting materials. The team here at Plyco often field a lot of question-based on this, with MDF regularly being the subject of these questions. With such a high demand for it, we thought it was best we addressed whether MDF panels are suitable for laser cutting.

Let’s cut to the chase; we do not recommend using MDF when laser cutting. Your materials need a very specific set of characteristics in order for you get the cleanest and most consistent cuts every single time, and unfortunately, MDF doesn’t offer that. To properly understand this you need to know how a laser cutter works.

We love our MDF products, but they're not suggested for laser cutting.

Laser cutters utilise a high-powered beam of concentrated light, which reach extremely hot temperatures. The laser gets so hot that rather than burning the wood away, it, in essence, evaporates it. This process helps keep the wood from being scorched or giving off a burned look despite being under immense heat because the wood is being placed under low thermal stress.

For a laser cutter to provide clean cuts on wood there are three key things needed in your material. Firstly, you need a compatible glue. If the incorrect glue is used and comes in contact with a laser you’ll see that sheet will start to burn up or just not cut at all, which is less than ideal. Secondly, you need an absence of core gaps, otherwise, bubbles will form and crack your wood. Finally, you need a product that is the right density, or you’ll produce very poor and ugly cuts.

MDF’s biggest problem with laser cutting also happens to be one of the products biggest strengths. MDF is just too dense. Usually, we’d praise the density and the strength it brings until the cows come home, but here it creates issues. You’ll struggle to get anything close to resembling a beautiful cut. You’ll also run into issues with the glue used. As the glue used with MDF is not optimal for laser cutting, the likelihood of you having a problem-free cut is drastically lowered. The one aspect it does succeed in is being free of core gaps, however, this one positive cannot make up for the rest of the drawbacks.

So, if MDF can’t be used for laser cutting what else is on offer?

Plyco has crafted our range of Laser Plywood for this specific reason. It’s not good enough to just grab any old piece of Plywood and start cutting away. You need something built specifically for this purpose, and luckily we’ve got you covered. All 12 of our Laserply products has been crafted to meet each of the three criteria and is held to the highest standards during the manufacturing process. Even better is that sheets are extremely affordable, so you don’t have to worry about your budget being blown because you can’t use the incredibly cheap MDF.

Now that know what kind of products are suitable for laser cutting, why not check out our online store? We ship Australia-wide, so no matter where you are we can give you your laser plywood fix. If you’d like to learn more about Laserply you can check out our comprehensive guide, or alternatively, you can browse some other MDF posts like how to paint MDF or the different types of MDF panels.

.svg)

.png)

.png)